Plastic Mat Weaving Machines

Process of manufacturing: 1. Polypropylene Granules are mixed with Master batch / pigment in a tumbler mixer and kept re

Description

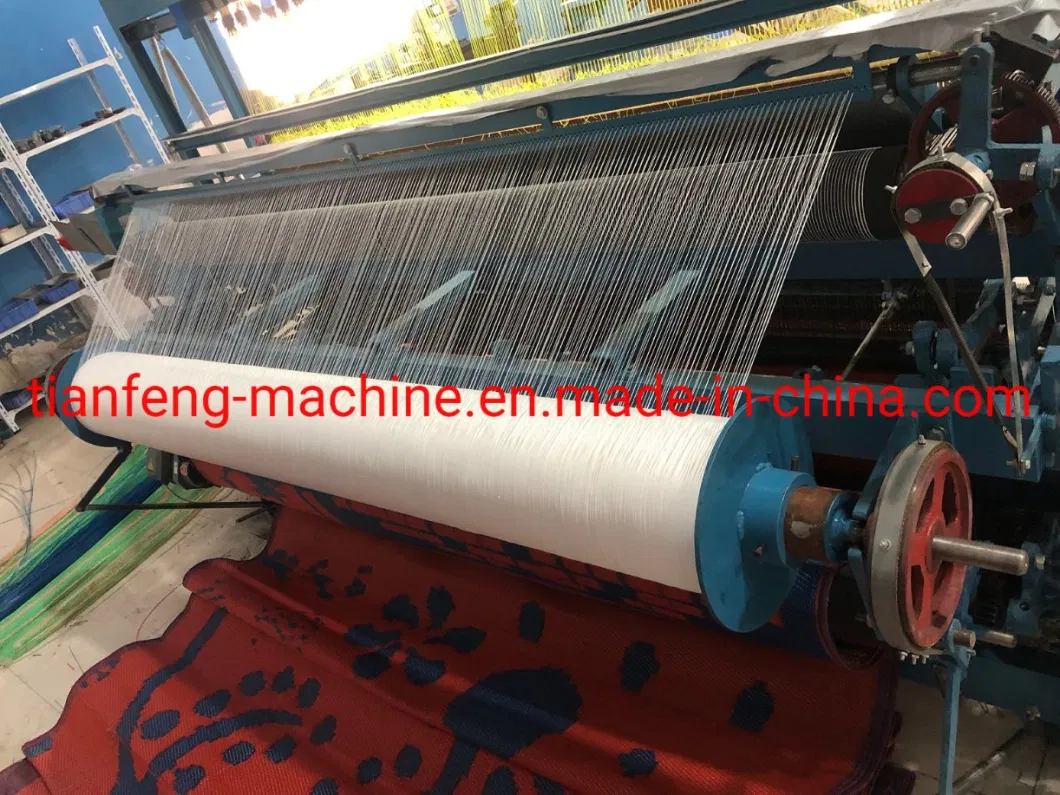

Basic Info.

| Model NO. | SJ |

| Origin | China |

| Production Capacity | 30set/Month |

Product Description

Process of manufacturing:

1. Polypropylene Granules are mixed with Master batch / pigment in a tumbler mixer and kept ready for extrusion.

2. Color mixed granules are put through an extrusion process wherein hollow tubes are produced of 1.8 2.00 MM OD.

3. The tubes so produced are preserved in a tray carefully to maintain straightness. These tubes are fed into the weaving machine hopper. Depending on the Jacquard design pattern colored tubes are selected for weaving. On the weaving machine PP filament yarn is being used as Warp and Tubes as Weft.

4. On the weaving machine mats are produced in roll form which are thereafter cut in lengths of 6/7 feet depending on the requirement on cutting and hot sealing machine.

5. After cutting the mats are inspected for fouls / faults and the same are rectified.

6. The finished mat is then taken on a sewing machine and the border tape is then stitched on both the sealed ends.

7. The finished mats are then packed in an attractive printed bag and bundled for dispatch.

Prev: PP PE Plastic Weaving Tarpaulin Water Jet Machine

Next: Talcum Powder Woven Bag Weaving Device Plastic Packaging Bag Machine

Our Contact

Send now