Industrial Fabric Making Finely Wire Mesh Weaving Rapier Loom Machine

Description

Basic Info.

| Model NO. | B |

| Precision | High Precision |

| Certification | CE, ISO9001: 2000 |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Yes |

| Wire Diameter | 0.02-0.27mm |

| Speed | 60-120times/Minute |

| Wire Material | Ss,Al,Copper,Brass,Nickel,etc. |

| Weight | 2500kg |

| Mesh Count | 0-600mesh |

| Weaving Width | 1300mm |

| Transport Package | Naked Cargo |

| Specification | 2400mm*2800mm*1250mm |

| Trademark | APM |

| Origin | Hebei, China |

| HS Code | 8446309000 |

| Production Capacity | 2000 Pieces/Year |

Packaging & Delivery

Package Size 240.00cm * 220.00cm * 120.00cm Package Gross Weight 2500.000kgProduct Description

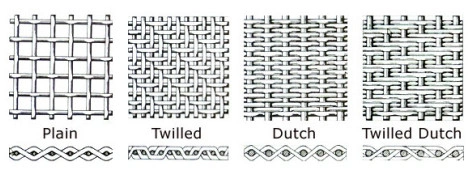

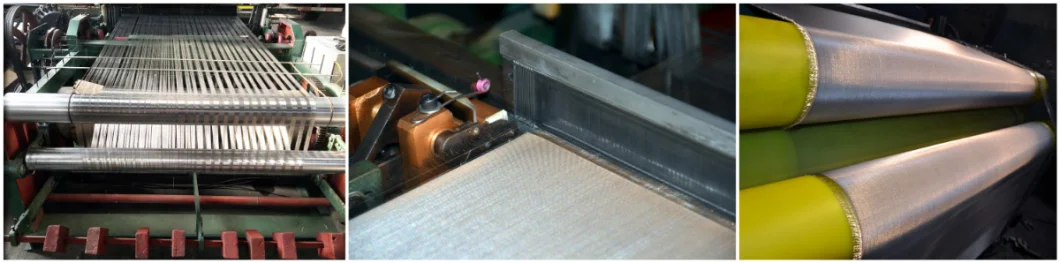

The machine is fully computerized numerical controlled and adopts PLC programmable control system, through servo motor and turbine reducer control cloth take-up and warp let-off to achieve automatic mesh tension adjustment, so that the mesh precision is high. Which can be more accurate weaving 80-600 square mesh with the standard wire diameter and also weave up to 2600 Dutch mesh, such as: plain weaving, Twill weave, Dutch weave and Reverse Dutch; The direct drive AC servo weft insertion can adjust the rapier return time and the length and time of the second pulling at will. The limit setting of the rapier belt not only effectively protects the rapier belt and head but also improves the safety factor of the rapier belt operation. The absolute encoder is used to prevent accidents and defects such as abnormal power failure, brake instability, and data loss resulting in the clamping of the rapier belt, making the operation more stable.The woven metal mesh is widely used in petroleum, chemical, machinery, aerospace and other industrial sectors of liquid, gas filtration and solid particle screening.

▪ All is full automatic ,such as warp wire feeding, shuttleless weft leading, rolling of mesh, braking and warning systems when the wire is

broken.

▪ Adaptability to various kinds of metal wire.

▪ Servo motor control.

▪ Automatic compensation of longitude wire and mesh rolling.

▪ Automatic stop and alarm for broken wire.

CNC machine Benefits:

CNC will adjust the mesh size automatic within the mesh range,

and keep the uniform opening size.

Length per roll could reach 500meter length.

It is better in filter industry wire mesh.

If the wire quality is better,the machine can work day and 24 hours working,night not need worker. you should do the perfect warping.

It reduces the labor cost due to the higher allocation of loom and productivity

The advantage of shuttle-less weaving:

- Firstly,weaving production is high due to the high speed of the machine.

- Secondly, it facilities defect-free cloth during weaving.

- Thirdly, shuttle less loom creates less noise.

- Then, the pirn winding process is eliminated in shuttleless loom.

- After that, it improves the quality of woven fabric and keeps better fabric value.

- Also, it needs low consumption of stores and spares.

- On the other hand, it is easy to market trades.

- Moreover, the accident percentage is low.

- Besides, easy maintenance and less workload for workers.

- Used for high-scale production.

- Particularly, it greatly eliminates the heavy weight weft carrier.

- In contrast,eliminates the movement of entire entire weft package.

- Besides,eliminates unnecessary to&pro movement.

- In fact,minimizes power consumption in picking

- Last but not least, the efficiency of shuttle less loom machine is higher than shuttle loom.

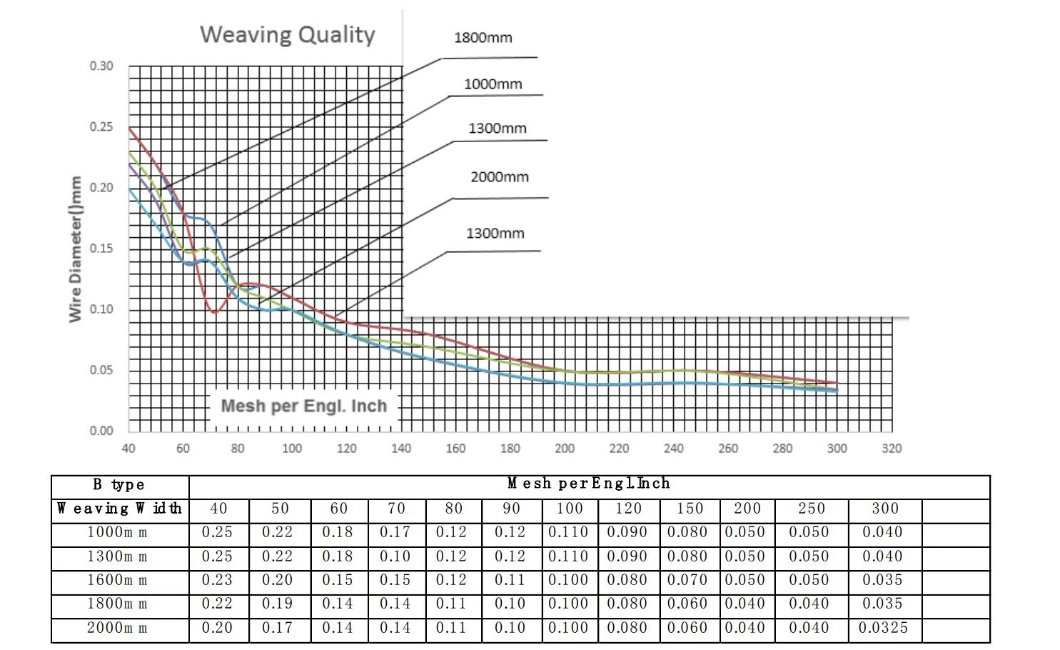

Product Parameters

| Machine Type | B |

| Weaving Width | 1300mm, 1600mm, 2000- 2500mm |

| Mesh Count | Square Mesh: 40-600Mesh Dutch Mesh: 2600Mesh |

| Warp/Weft Wire Range | Blow 0.30mm |

| Speed | 60-120timie/min |

| Driver Way | Electromagnetic Brake Motor Driver, Variable frequency Speed Regulation |

| Heddle Frame | 2 or 4 or 5 |

| Shedding Mechanism | Aluminum heddle frame, Cam Shedding |

| Beating Mechanism | The crankshaft is a 65mm diameter, 45 (55) steel monolithic forging, and the sley (55 square steel) is made of carbon structural steel after heat treatment; |

| Weft Insertion | 2.3KW high performance AC servo motor direct drive, The guild wheel drive the carbon fiber rapier belt to do reciprocating weft insertion motion |

| Warp let-off System | Servo motor drive, wire electronic tension feedback control, double rear beam, negative swinging rear beam stabilizing mechanism |

| Cloth Take-up System | Servo motor drive, digital display braid length Servo measure mesh account |

| Control System | New weaving machine control system |

Full PLC

3 servo motor

Endless cloth take-up(3 rollers to take up the cloth without machine stop when cut the cloth off)APM-SWJ-1300B/1600B

Full PLC

2 servo motor(rapier driven by gear)

Endless cloth take-up(3 rollers to take up the cloth without machine stop when cut the cloth off)APM-SWJ-1300B/1600B

Full PLC

3 servo motor

Limited cloth take-up(single roller to take up cloth,must stop the machine when cut off the cloth)

Company Profile

Hebei Zonghang Machinery manufacture is new name for export and the old name is Jinjingwei Machinery manufacture which

began to operate in 1983 and divided from our machinery factory in 1995. We are only professional in weaving wire mesh

machine for over 20years old.

Our main machine range: Crimped wire mesh weaving machine, Shuttleless wire mesh weaving machine, knitting mesh machine,

Expanded metal mesh machine, Razor barbed wire machine, etc.

With the good service an high technology quality machine, We got proved and praise from our clients. From 2008 to till now. Our

machine are widely exported to India, Egypt, France. Iran, Indonesia. Malaysia. Jordan, Bahrain and Africa etc. 25countries till now.

After Sales Service

Sale service:

Maintenance period: one yearWe can send our technicist to the buyers' place to debug the machine and providing the training in 30 days after the machines arrive at the destination port.

The debugging fees: free

The training fees: First 7days is free , after that USD100/day for each technical

The numbers of technical persons: one technical person per machines at most.

The fees :round-trip tickets, accommodation etc, are all in buyers' account.

During the maintenance period:the parts damaged non-artificially will be provided free of charge. If buyers need the technicians,we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

After the maintenance period:If buyers need the machine parts, we will provide it as our cost. If buyers need the technicians, we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

Auxiliary machineMore products

Prev: Automatic Window Screen Mesh Machine (width of weaving: 2000mm)

Next: Automatic Crimped Wire Weaving Mesh Machine for Mineral and Coal Filter Made in China

Our Contact