Electronic Dobby Shedding Water Jet Loom Weaving Machine

Description

Basic Info.

| Model NO. | JW408 |

| Customized | Customized |

| Condition | New |

| Weft Insertion Rate | 2280m/Min |

| Weft Feeder | 1, 2, 3, 4 Color |

| Pump | Single or Double |

| Bearing | NSK, FAG, SKF |

| Shedding Type | Crank, Cam, Dobbyor Jacquard |

| Nozzle | Mdh Korea |

| Reed Width | 170, 190, 210, 230, 260, 280, 340, 360cm |

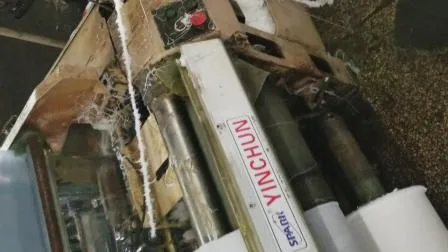

| Transport Package | Standard Export Packing |

| Trademark | SPARK |

| Origin | Qingdao, China |

| HS Code | 8446304000 |

| Production Capacity | 500sets/Month |

Product Description

Product Description

JW408 is a brand new type water jet loom which suitable for weaving the fabrics from light to medium heavy fabrics.and is the mainstream of fourth generation type machine to instead of Tsudakoma 817,851 type.Now its already become one matural model ,and be recognized by both demestic customer and foreign customer.Product Parameters

Technical Parameter:Nominal width adjustment range: 0-50cmYarn weaving range: 50-420Weft density range (/10cm): 50-600Weaving shaft disc diameter (mm): 800Maximum winding diameter: 420-520Open type: crank shedding, cam shedding, dobby sheddingControl system: W2000 type control system or SD350Beating up mechanism: bilateral rigid connection four-pod beating upSelvage form: raw selvageWeft insertion mechanism: high pressure water flowWeft insertion device: photoelectric weft insertion deviceHinge device: planetary gear selvageWeft cutting: mechanical scissorsLet-off: Electronic let-off or mechanical let-offTake-up: electronic take-up or mechanical take-upDehydration: negative pressure dehydration, vertical drainageHeddle frame maximum frames: 16pcsLubrication system: oil bath, heavy oilWater pressure: tap water pressure

Our Advantages

W408-190 Heavy Water Jet Loom

The JW408-190 heavy water jet loom is optimized on its structure and operation parts, featuring a high degree of mechanical and electrical integration, reaching an ultra-performance with high speed and energy saving function.With improving the weft insertion mechanism, it greatly reduces vibration and noise ,meanwhile highly enhances solidity and stability of the machine.Using separate nozzle holder, it sets each nozzle with individual position and direction. The super start-up motor and large capacity electromagnetic brake having achieved the closing down of machine at a right position.The adoption of new energy-saving nozzle makes it true to sharply reduce water consumption.After Sales Service

Spark is committed to offering high-quality spare parts to deliver maximum productivity with minimum downtime. Our spare parts policies are:

- Vulnerable parts whose value is equivalent to 5% of the overall machine price are freely provided.

- Within a one-year warranty, vulnerable parts are freely repaired or replaced. Out of warranty, customers need to pay the replacement part cost and freight fee.

- Our experienced technicians are skilled in offering technical support and training services to help your weaving looms remain efficient and stable.

- After delivery, Spark provides a 15-day to 1 month (depending on the loom quantity) of in-house training at the customer's location. Training includes weaving machine installation and debugging. The training and installation fee is $50/day.

- Within 15 days after on-site debugging, our technicians will stay at your factory to observe the running status of looms and ensure there are no problems.

- Spark offers 24/7 technical support and troubleshooting service via phone, e-mail, text, WeChat or WhatsApp, Skype, and Line.

- You can assign your engineers to come with us for a technical exchange.

Prev: Shandong Rifa Brand 340 Cm Cam Shedding Air Jet Loom

Next: Tongda Double Nozzles Plain Cam Dobby Shedding Weaving Air Jet Loom

Our Contact